IIoT Solutions

Unlock the Power of Connected Devices and Data Analytics in Industrial Operations. Experience Efficiency, Productivity, and Innovation.

What is IIoT?

The Industrial Internet of Things (IIoT) refers to the network of interconnected devices, sensors, machines, and systems within industrial environments. These devices collect, exchange, and analyze data in real-time, enabling intelligent decision-making and automation of industrial processes.

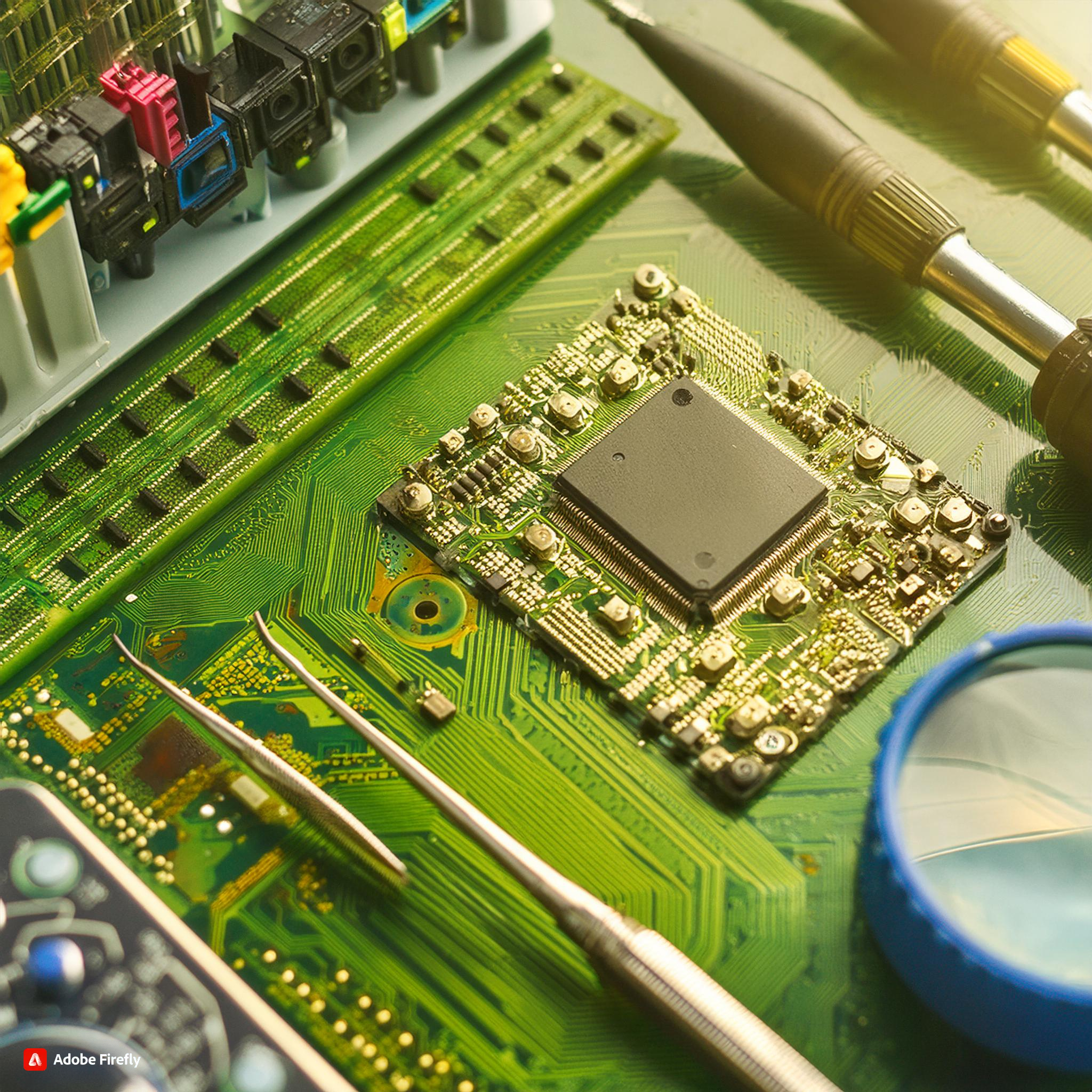

Key Components of IIoT

Sensors and Devices

IIoT relies on a wide range of sensors and devices, including temperature sensors, pressure sensors, actuators, and RFID tags, to collect data from industrial equipment and assets.

Connectivity

IIoT systems leverage various communication technologies, such as Wi-Fi, Bluetooth, and cellular networks, to transmit data between devices and centralized systems.

Edge Computing

Edge computing enables data processing and analysis to occur closer to the source of data generation, reducing latency and enabling faster response times in IIoT applications.

Benefits of IIoT

1. Real-time Monitoring

IIoT enables real-time monitoring of equipment, processes, and assets, allowing for proactive maintenance and optimization of operations.

2. Predictive Maintenance

By analyzing data from sensors and machines, IIoT systems can predict equipment failures and schedule maintenance before issues arise, minimizing downtime and reducing maintenance costs.

3. Optimized Efficiency

IIoT facilitates the optimization of energy usage, resource allocation, and production processes, leading to improved efficiency and cost savings.

4. Enhanced Safety

IIoT systems help identify safety hazards and monitor environmental conditions in industrial settings, promoting a safer work environment for employees.

5. Data-driven Insights

IIoT generates vast amounts of data that can be analyzed to gain valuable insights into operations, customer preferences, and market trends, enabling data-driven decision-making and strategic planning.

Applications of IIoT

Predictive Maintenance

IIoT enables predictive maintenance strategies by monitoring equipment health and performance in real-time, predicting failures before they occur, and scheduling maintenance proactively.

Asset Tracking and Management

IIoT systems track the location, status, and condition of assets and inventory in real-time, improving asset utilization, inventory management, and supply chain visibility.

Smart Manufacturing

IIoT enables the implementation of smart manufacturing initiatives, such as smart factories and digital twins, which optimize production processes, improve quality, and increase flexibility.

Energy Management

IIoT systems optimize energy usage by monitoring and controlling energy-consuming devices and systems, identifying inefficiencies, and implementing energy-saving measures.

Environmental Monitoring

IIoT sensors monitor environmental conditions, such as air quality, temperature, and humidity, in industrial settings, ensuring compliance with regulatory standards and promoting sustainability.

Our Expertise in IIoT

At Masar Tech, we specialize in designing and implementing IIoT solutions tailored to the unique needs and challenges of industrial organizations. Our team of experts combines domain knowledge with cutting-edge technology to deliver scalable, secure, and robust IIoT solutions that drive tangible business outcomes.